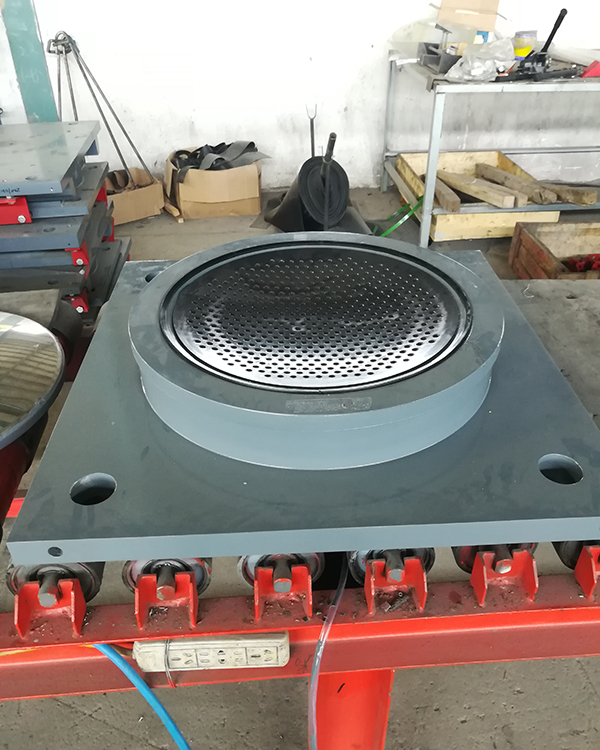

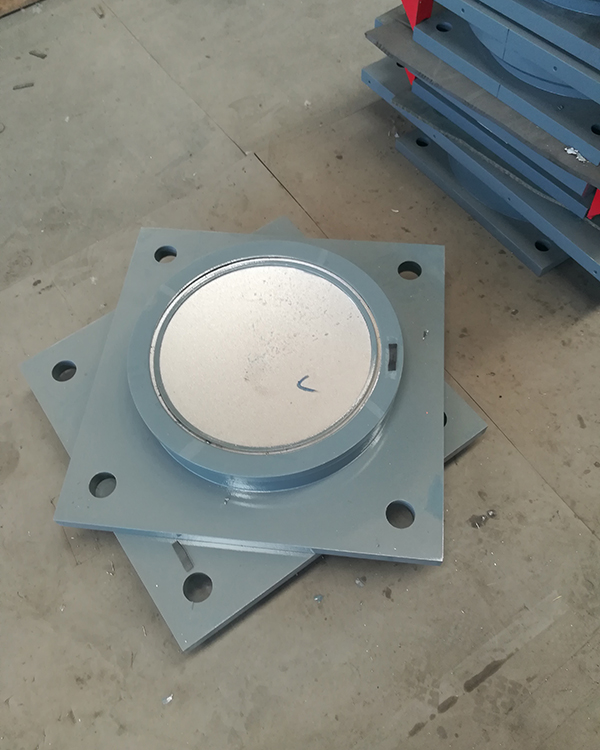

There is a concave spherical surface in the middle of the lower plate, which corresponds to the convex middle plate. There is an arc-shaped PTFE plate lined between the two. The spherical surface slides with it to satisfy the rotation of the beam end; the stainless steel plate on the upper seat plate is on the middle steel plate. The other tetrafluoroethylene plate constitutes the second sliding surface, which completes the stretching and braiding displacement of the beam due to many reasons of temperature difference.

1. The ball bearing transmits force through the spherical surface, and there is no force necking phenomenon, and the reaction force acting on the concrete is relatively uniform;

2. The ball bearing realizes the rotation process of the bearing through the sliding of the spherical polytetrafluoroethylene plate. The rotating torque is small, which is especially suitable for the requirements of the corner. The design corner can reach more than 0.05rad;

3. The bearing has the same rotating performance in all directions, which is suitable for wide bridges and curved bridges;

4. The bearing does not need to be pressured by rubber, and there is no influence of rubber aging on the rotation performance of the bearing. It is especially suitable for low temperature areas.